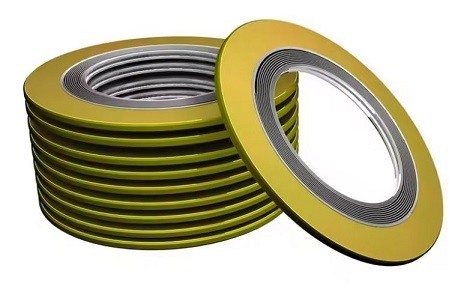

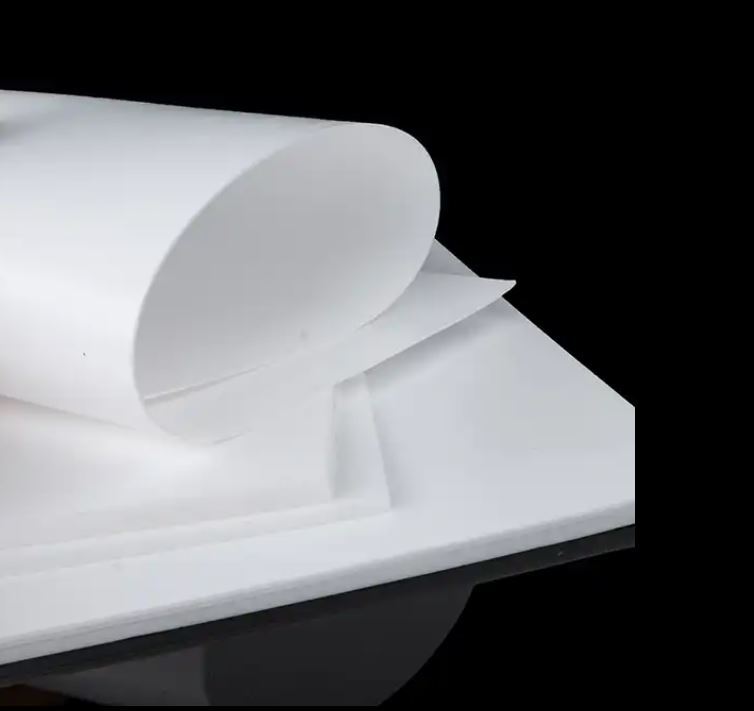

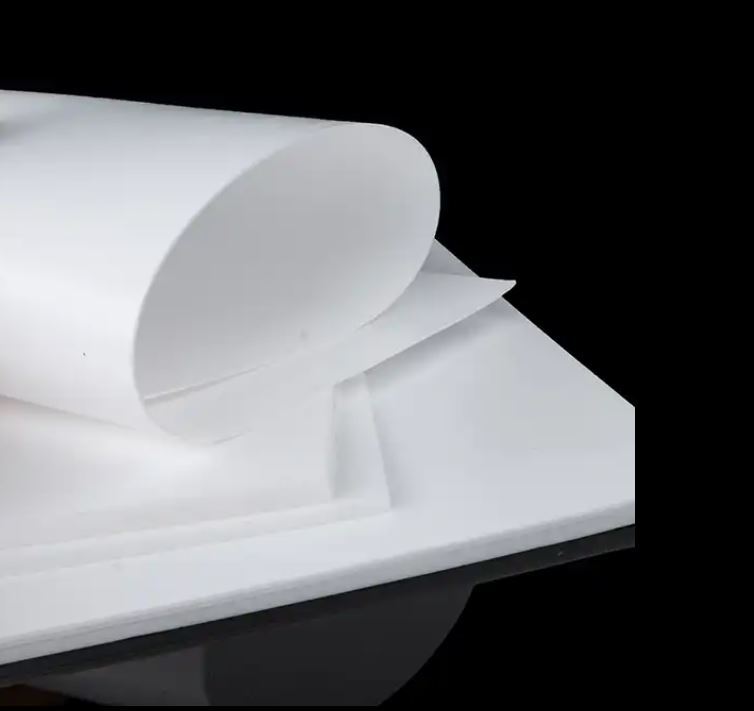

Expanded PTFE (can be supplied as Full Sheet, Custom Cut Sheet, flange gaskets, Ring gaskets, Custom Gaskets, rubber strips, washers)

Expanded PTFE (Polytetrafluoroethylene) gasket material, also known as ePTFE, is a versatile sealing material derived from virgin PTFE. Unlike virgin PTFE, which is a solid material, expanded PTFE undergoes a manufacturing process that creates a highly porous structure, resulting in unique properties ideal for gasket applications. Here are more details about expanded PTFE gasket material:

Porous Structure: The manufacturing process involves stretching virgin PTFE to create a highly expanded and porous structure. This expansion increases the material’s compressibility and conformability, allowing it to conform to irregular or rough surfaces more effectively.

Soft and Flexible: Expanded PTFE is soft and conformable, making it suitable for sealing applications where tight sealing against irregular surfaces or low bolt loads is required. Its flexibility enables it to adapt to flange imperfections, reducing the risk of leakage.

Excellent Sealability: The unique structure of expanded PTFE provides excellent sealability, even under low bolt loads. It forms a tight seal against flange surfaces, preventing leaks of gases or fluids across a wide range of temperatures and pressures.

Chemical Resistance: Similar to virgin PTFE, expanded PTFE offers outstanding chemical resistance, making it resistant to a wide range of corrosive chemicals, solvents, and acids. This property makes it suitable for use in chemical processing, pharmaceutical, and petrochemical industries.

Temperature Resistance: Expanded PTFE maintains the high-temperature resistance of virgin PTFE, withstanding temperatures ranging from -180°C to 260°C. This temperature resistance ensures its suitability for applications involving extreme temperature variations.

Low Creep Relaxation: Expanded PTFE exhibits low creep relaxation, meaning it maintains its sealing integrity over time, even under continuous compression. This property contributes to the long-term reliability of gasket joints, reducing the need for frequent maintenance or replacement.

Non-stick Properties: Similar to virgin PTFE, expanded PTFE possesses non-stick properties, which prevent adhesion of contaminants or debris to the gasket surface. This property helps maintain a clean and hygienic sealing environment, particularly in food and pharmaceutical applications.

FDA Approval: Expanded PTFE gasket material often complies with FDA regulations for food-contact applications, ensuring its suitability for use in food processing and pharmaceutical manufacturing where regulatory compliance is essential.

Electrical Insulation: Like virgin PTFE, expanded PTFE retains excellent electrical insulation properties, making it suitable for applications where electrical isolation is required.

Compatibility: Expanded PTFE gasket material is compatible with a wide range of flange materials, including metallic and non-metallic surfaces, providing versatility in sealing various types of connections.

Overall, expanded PTFE gasket material offers unique properties such as excellent sealability, chemical resistance, and conformability, making it a preferred choice for demanding sealing applications across various industries.

- Thicknesses Available: 1.5mm, 3mm

To place an order or if you require any further more information, please simply click here to Call Us or Email US.