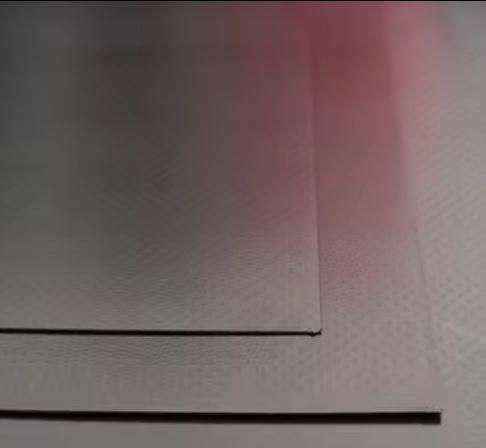

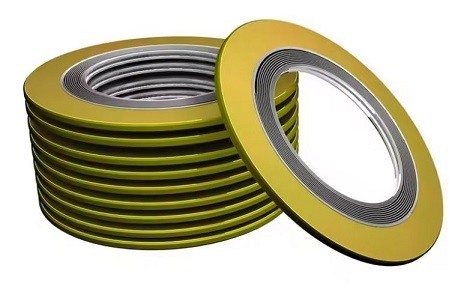

Ferolite NAM-42 GF can be supplied as Full Sheet, Custom Size Cut Sheet, flange gaskets, Ring gaskets, Custom Gaskets, strips, Blocks, washers.

Ferolite NAM-42 GF is a specialized gasket material renowned for its exceptional mechanical strength, chemical resistance, and thermal stability, making it a preferred choice for demanding sealing applications across various industries.

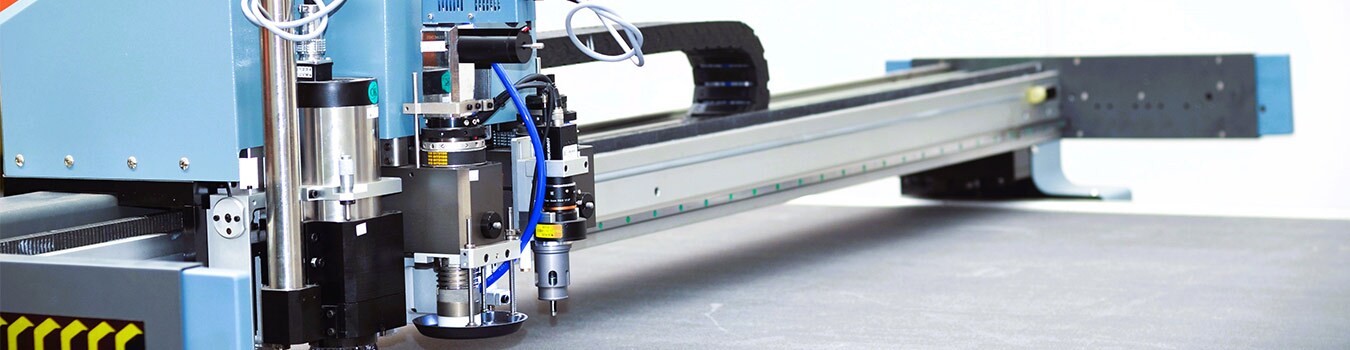

Our services extend to precision cutting of this material into various forms such as flange or ring gaskets, customized to your specific needs. Alternatively, we welcome your designs or samples for tailored production. Moreover, we can supply this material in sheet1500mm x 2000mm.

Here’s a detailed description of Ferolite NAM-42 GF:

Composition: Ferolite NAM-42 GF is a non-asbestos gasket material composed of a blend of aramid fibers, mineral fibers, and fillers bound together with a high-quality nitrile rubber (NBR) binder. The aramid fibers provide excellent tensile strength and resistance to mechanical stress, while the mineral fibers enhance the material’s thermal stability and resistance to high temperatures.

Mechanical Strength: Ferolite NAM-42 GF exhibits exceptional mechanical strength and dimensional stability, making it suitable for applications where high bolt loads and compressive forces are present. Its robust construction ensures reliable sealing performance, even under challenging operating conditions.

Chemical Resistance: The nitrile rubber binder in Ferolite NAM-42 GF provides excellent resistance to oils, fuels, hydrocarbons, and other common industrial chemicals. This chemical resistance makes it suitable for use in applications involving exposure to petroleum-based products and aggressive chemicals.

Thermal Stability: Ferolite NAM-42 GF maintains its sealing integrity over a wide temperature range, from temperatures up to 300°C. Its thermal stability ensures reliable performance in applications where temperature fluctuations are common, such as in heat exchangers, boilers, and exhaust systems.

Compressibility and Conformability: Despite its mechanical strength, Ferolite NAM-42 GF remains highly compressible and conformable, allowing it to adapt to irregular flange surfaces and create a tight seal. Its ability to conform to surface imperfections ensures leak-free performance in critical sealing applications.

Versatility: Ferolite NAM-42 GF is available in various thicknesses and sheet sizes, offering versatility to suit different sealing requirements. It can be easily cut or punched into gaskets of different shapes and sizes, making it suitable for a wide range of flange connections, pumps, valves, and other equipment.

In summary, Ferolite NAM-42 GF offers a high media resistance to many of the aggressive media. It exhibits good sealing and torque retention properties. It is specifically designed to satisfy the growing demand for numerous aggressive chemicals used by industry today. An excellent material for high stress condition. It can also be used for sealing oils, fuels, gases, freons, and general application in paper & pulp industry for application in pipelines, radiators, boilers and many other instances of flanged joints.

Ferolite NAM 42 GF exhibits comparable properties to various other brand gasket materials on the market such as Donit Tesnit BA-GL, Klinger C4430, Teadit NA1005, Garlock 5500, Novus 34, Flexitallic SF3300, and James Walker Centurion. The material shares similarities in terms of its sealing capabilities, temperature resistance, and chemical compatibility. This makes Ferolite NAM 42 GF a versatile choice for applications where performance criteria align with those of other renowned brands in the gasket industry.

Premium Quality at Affordable Price: Ferolite NAM-42 GF is a premium quality material offered at a more affordable price, providing cost-effective sealing solutions without compromising on performance or reliability.

- Material Composition : Aramid Fibre, Mineral Fibre & Glass Fibre.

- Max.Peak Temp : 440°C

- Max. Continuous Temp :350°C

- Max.Continuous Temp.with steam : 250°C

- Max. Operating Pressure : 150 Kg/cm2

- Material Thickness: 0.5, 1, 1.5, 2.0, 3.0 mm

- Sheet Size: 1500mm x 2000mm

To place an order or if you require any further more information, please simply click here to Call Us or Email US.