Tanged graphite sheet can be supplied as Full sheet , Custom Cut Sheet, flange gaskets, Ring gaskets, Custom Gaskets, Blocks, washers.

Tanged graphite gasket material is a specialized sealing material renowned for its exceptional thermal and chemical resistance, making it ideal for demanding high-temperature and corrosive applications. Here’s a detailed description of tanged graphite gasket material:

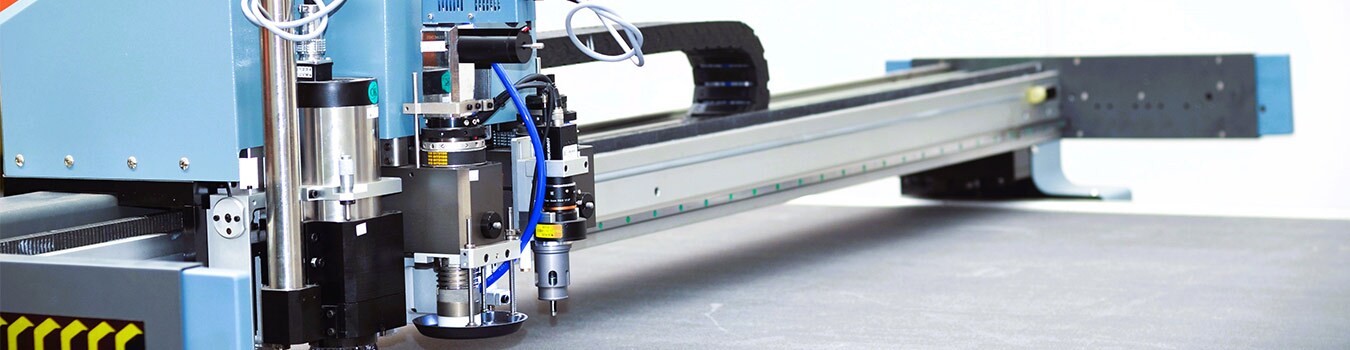

Composition: Tanged graphite gasket material typically consists of layers of flexible graphite sheets reinforced with a perforated stainless steel tang core. The tang core provides mechanical strength and stability to the graphite sheets, enhancing their handling and installation properties while maintaining the flexibility necessary for conforming to irregular surfaces.

High Temperature Resistance: Tanged graphite gasket material exhibits exceptional thermal resistance, capable of withstanding temperatures ranging from cryogenic levels to extreme heat. It maintains stability at temperatures up to 500°C in oxidizing environments and even higher temperatures in inert or reducing atmospheres.

Chemical Compatibility: Graphite is inherently inert and resistant to most chemicals, acids, and solvents. Tanged graphite gasket material is suitable for use in corrosive environments where other sealing materials might fail, ensuring long-term sealing integrity in applications such as chemical processing, petrochemical refining, and pharmaceutical manufacturing.

Low Leakage Rates: The flexibility of Tanged graphite gasket material allows it to conform tightly to mating surfaces, creating a reliable seal with minimal leakage rates, even under high pressures and temperature cycling. This property ensures effective containment of fluids or gases in critical applications.

Conductivity: Graphite exhibits good electrical conductivity, making Tanged graphite gasket material suitable for use in applications requiring electrical grounding or conductivity. It can effectively dissipate static electricity or provide a conductive path in electrical enclosures or equipment.

Versatility: Tanged graphite gasket material is available in various thicknesses and sheet sizes, allowing for customization to fit specific application requirements. It can be used in a wide range of sealing applications, including flange connections, heat exchangers, pumps, valves, and reactors, across industries such as oil and gas, chemical processing, power generation, and aerospace.

In summary, Tanged graphite gasket material offers outstanding thermal resistance, chemical compatibility, sealing performance, and versatility, making it a preferred choice for demanding sealing applications where reliability and durability are paramount.

Material Thickness: 1.5mm, 3mm

Sheet Size: 1500mm x 1500mm

To place an order or if you require any further more information, please simply click here to Call Us or Email US.

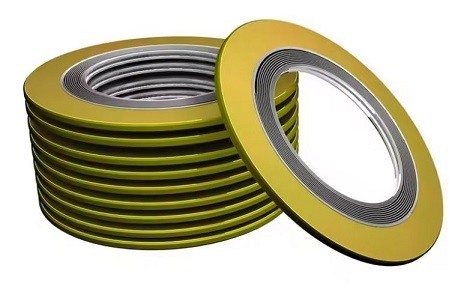

Tanged Graphite Flange Gaskets

Tanged graphite gaskets are a specialised sealing material designed to withstand extreme temperatures, high pressures, and aggressive chemicals. They are ideal for use in demanding environments where standard sealing materials may fail. With their unique construction, which combines flexible graphite sheets and a perforated stainless steel tang core, tanged graphite gaskets provide a reliable seal while offering enhanced durability. Commonly used in petrochemical, oil and gas, power generation, and manufacturing, these gaskets ensure a secure seal in critical applications.

Read More

Why Choose Tanged Graphite Gaskets?

Our tanged graphite gaskets offer several key advantages, making them the go-to choice for high-performance applications:

- Composition: Made from pure expanded graphite sheets reinforced with a perforated stainless steel core, these gaskets provide flexibility and durability. The steel tang reinforcement enhances the gasket’s structural integrity, ensuring easy handling and installation.

- Exceptional Thermal Resistance: Able to perform across a wide temperature range, these gaskets can withstand conditions from cryogenic levels up to 500°C in oxidising environments, and even higher in inert or reducing conditions. This makes them suitable for both hot and cold applications where stability is essential.

- Chemical Resistance: Graphite’s inert nature ensures compatibility with a wide range of chemicals, acids, and solvents. This makes tanged graphite gaskets suitable for use in highly corrosive environments, such as those found in chemical processing and oil refining.

- Mechanical Strength: The perforated stainless steel tang reinforcement offers superior strength, ensuring easy handling during installation without sacrificing the gasket’s ability to conform to irregular surfaces.

- Low Leakage Rates: The flexibility of the graphite layers allows these gaskets to form a tight seal against mating surfaces, resulting in minimal leakage rates.

- Electrical Conductivity: Graphite’s conductive properties make tange graphite gaskets suitable for applications requiring electrical grounding or dissipation of static electricity.

- Thickness and Sheet Sizes: Available in 1.5mm and 3mm thicknesses, with standard sheet sizes of 1500mm x 1500mm. Custom cut sheets and sizes can be tailored to fit specific applications.

Applications Across Industries

Tanged graphite gaskets excel in various demanding industries, providing reliable sealing solutions. In petrochemical and chemical processing, they ensure long-term performance in high temperatures and aggressive chemical exposure. The oil and gas sector relies on these gaskets for pipelines, valves, and pressure vessels, delivering a dependable seal even under fluctuating pressures. In power generation, they are used in boilers and heat exchangers, maintaining integrity in extreme heat for efficient operation. Their flexibility and strength make them suitable for aerospace and manufacturing, where precision and durability are critical.

Find the Right Tanged Graphite Gasket for Your Needs

At Industrial Experts, we specialise in delivering high-quality tanged graphite gaskets that meet the demanding requirements of your industry. Our team is ready to assist with any custom specifications you may have, offering expert guidance and competitive pricing. Get in touch today to discuss your needs and find the right gasket solution for your project.

Discover our wide range of gaskets, including rubber,ring, PTFE, cork, CNAF, flange, and spiral wound, or explore different materials for your next project, such as neoprene,nitrile, EPDM, natural insertion, and silicone. Trust Industrial Experts to deliver the expertise you need in sealing.